Usages of carbon steel and stainless steel in Industry

Steel with chromium and maybe other alloying elements added to it, most notably nickel, is known as stainless steel. Inox steel gets its name because it is ‘in oxidable,’ or oxidation-resistant. During iron rusts, when exposed to air, chromium does not oxidise when in the same condition. Nevertheless, carbon steel contains significantly less chromium and mostly carbon and iron with minimal additions of other elements. Thus, it is possible to label it as “low-alloy” steel. This basic composition is shared by both stainless steel and carbon steel; nevertheless, carbon steel is distinguishable from stainless steel due to its higher carbon content. Here are several examples

- 304 stainless steel pipe fittings

304 stainless steel pipe fittings are one of the most popular types of stainless steel because they have high tensile strength, don’t rust, and are flexible. They are made of austenitic-grade stainless steel, distinguished by their high chromium concentration. As a result, they are incredibly dependable and long-lasting.

- 304 stainless steel flanges

The austenitic 304 stainless steel flanges used to make the flanges is an 18/8 chromium-nickel alloy. The lowest yield strength of the material is 205MPa, and the minimum tensile strength is 515MPa. Therefore, it is quite sturdy. A flange made from ASTM A182 Grade F304 pipe can be used for anything requiring a pressure-tight seal, including vessels under pressure.

- Stainless Steel Pipe fittings

As a result of their superior craftsmanship, adaptability to a wide range of applications, and attractive design, Stainless Steel Pipe fittings are in high demand. The wide range of components they incorporate is what gives them flexibility, but it also makes them somewhat pricey. It’s resilient under stress and produces superior outcomes.

- Stainless Steel flanges

Flanges made of stainless steel can be easily inspected, cleaned, and repaired. Stainless Steel flanges are fabricated from a variety of stainless-steel alloys. Several grades of stainless steel exist, each with its unique chemical makeup and mechanical properties. The SS Flange is made from a low-carbon, highly austenitic material that resists corrosion exceptionally well. Scrubber assemblies have multiple applications.

- Carbon steel flanges

Forged carbon steel flanges connect pipes to devices like pressure vessels, valves, and pumps. ASTM A3015, ASTM A182, ASTM 694, and ASTM A105 are the most often encountered grades for Carbon steel flanges. Flanges made from carbon steel can have a maximum carbon content of 2.1%.

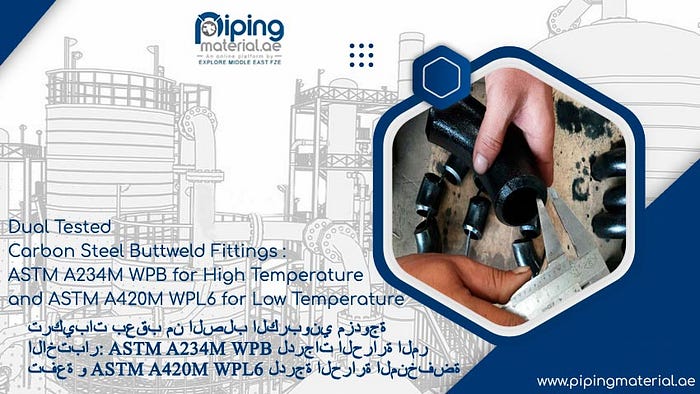

- Carbon Steel Pipe Fittings

The carbon steel pipe fittings enable flow rerouting, downsizing pipes, and joining or branching off of other piping components. Depending on the application, these fittings take their starting material from welded or seamless pipe. They are formed into reducer tees, elbows, owlets, and caps using hot and cold forming processes.

Conclusion

Steel comes in numerous forms, but carbon steels and stainless steels are the two most common. While all steels have iron and carbon as their primary constituents, their alloying elements can vary widely. It’s common for carbon steel to have a lower chromium concentration than 10.5%, but stainless steel requires at least that much. These variations give each kind of steel its unique qualities.

Comments

Post a Comment