Many kinds of steel plates

Flat steel plates can be worked into more intricate forms using cutting and welding. It is determined as the high-temperature steel is rolled into a plate what its ultimate strength will be. A steel object is made by compressing and forging successive layers of steel into the desired shape and size. Several steel plates in various forms are presented here.

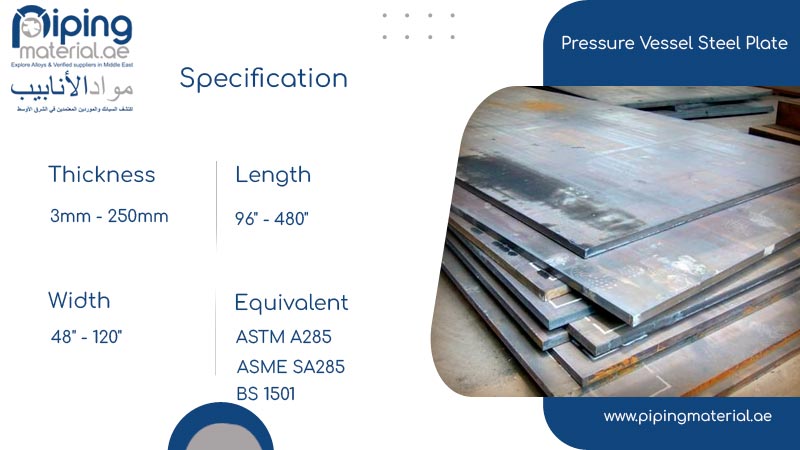

- Steel plate for pressure vessels

The steel used in pressure vessels serves to contain fluids and gases. The high-strength Pressure vessel steel plate processes and stores components under high pressure. Steels with different compositions and properties make carbon, stainless, and alloy varieties for use in pressured vessels.

- Weathering steel plate

In a corrosive environment, weathering steel plate suppliers provides plates which are chemically composed of phosphorus, copper, nickel, silicon, and chromium. This coating prevents the steel from rusting and breaking down more.

- Abrasion Resistant plate

Abrasion Resistant plate suppliers, short for abrasion resistance, is a high-carbon alloy steel type. Hence, AR is more durable because of the incorporation of carbon and more malleable and resistant to the elements because of the incorporation of alloys. The toughness and hardness of a steel plate are greatly improved by adding carbon during its manufacture at the expense of its strength.

- Carbon steel plate

Carbon steel plate suppliers provides steel sheets that have been carbonitrided to increase strength. By doing this process, the steel is heated in an oxygen-free environment and then quenched in oil. Carbon steel is commonly used for structural purposes because of its malleability and ease of machining.

- Manganese Plate

Manganese steel, often known as Mangalloy, is an alloy that contains roughly 13 percent manganese by weight. The Manganese Plate chemical makeup has a healthy amount of carbon. Impact resistance and abrasion resistance are two notable qualities displayed by these plates.

- Quenched & tempered steel plate

Steel and other iron-based alloys can be strengthened and hardened through Quenched & tempered steel plate. Quenching, or quench hardening, is when the material is heated and rapidly cooled to harden and set the components. The type of material satisfied and the required hardness inform the heating temperature, cooling technique, cooling substance, and cooling pace.

- Copper nickel plate

A thin layer of copper or other metals is deposited onto the component's surface, plated by an electroplating technique called Copper nickel plate suppliers. This way, corrosion and wear are warded off from the underlying metal. Steel, brass, aluminium, and stainless steel are ferrous and non-ferrous metals that can benefit from this procedure.

- Compression fittings

If you need to connect two tubes or thin-walled pipes, you can do so with Compression fittings suppliers commonly used in plumbing and electrical conduit systems. Lines constructed of different materials require fittings made of the same or similar materials to ensure a secure connection. Common examples include PVC and copper, which require fittings made of PVC and copper.

Conclusion

When it comes to corrosion and wear and tear, steel plate has you covered. Compared to regular steel sheets, they can be produced in a wider variety of thicknesses. Super-structural frameworks and unbreakable durability are typical uses for plate steel. It's manufactured for structural services but can also be used in simple fixes. Steel Plate like Boiler steel plates suppliers can withstand extreme temperatures and pressures.

Comments

Post a Comment